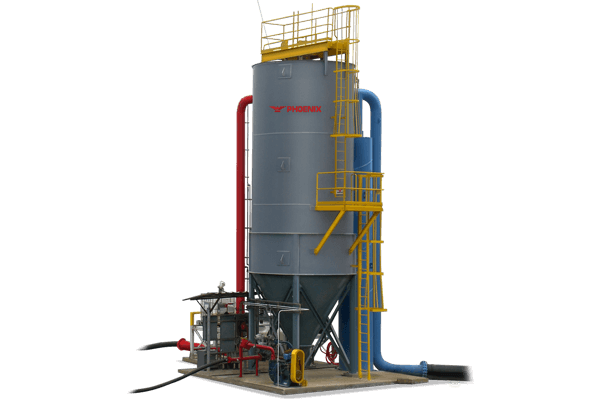

The PHOENIX AltaFlo™ Thickener is a rake-less thickener that provides ultra high-rate mixing, flocculation, and internal dilution followed by clarification and positive sludge collection and removal in a single tank. The Thickener's unique internal geometry, a deep sidewall and steep conical bottom provides underflow concentration comparable to or better than a traditional raked thickener. Internal dilution helps optimize flocculation and a deep free settling zone and conical feed well achieves maximize flocculation. In addition, the AltaFlo™ Thickener uses sedimentation technology to maximize the recovery rate of clean, clarified overflow water that can be recycled and reused in the process.

AltaFlo™ slurry thickeners are available in several sizes, general or seismic design, with options including local control panel, bed level sensor and pressure transmitter.

For complete elimination of the slurry pond, a PHOENIX Belt Filter Press or Filter Press may be added downstream of the AltaFlo™ Thickener to dewater the thickened slurry.

AltaFlo™ slurry thickeners are available in several sizes, general or seismic design, with options including local control panel, bed level sensor and pressure transmitter.

For complete elimination of the slurry pond, a PHOENIX Belt Filter Press or Filter Press may be added downstream of the AltaFlo™ Thickener to dewater the thickened slurry.

Slurry sinks, solids settle out, water enters clear water zone, coarse conglomerates sink & smaller particles enter cone.

Slurry sinks, solids settle out, water enters clear water zone, coarse conglomerates sink & smaller particles enter cone.