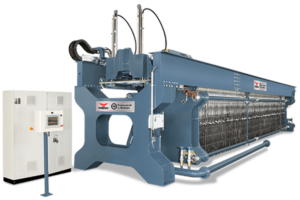

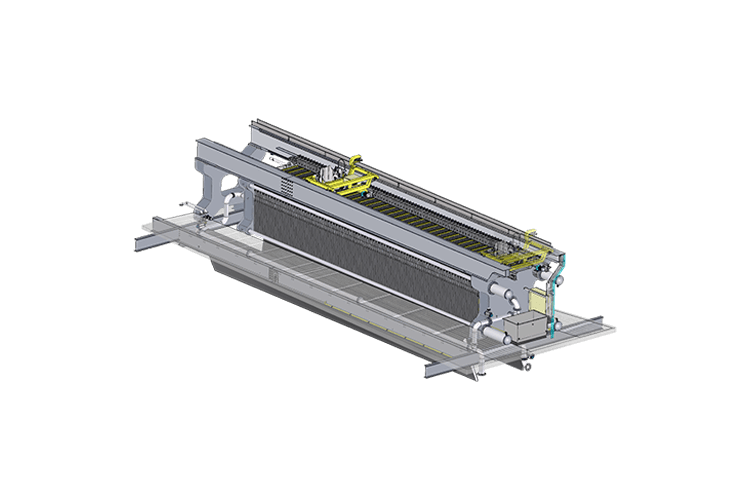

The PHOENIX Filter Press dewaters concentrate and tailings slurries to produce high solids filter cake. This ruggedly built, fully automatic chamber and membrane filter press is reliable, fast, and offers high volume dewatering resulting in the driest cake possible. Whether you need the high production capacity of an Overhead Beam Filter Press or the smaller Side Beam design, PHOENIX offers many customized options to best fit your need.

PHOENIX Filter Presses feature high speed robotic plate shifters for fast cycle times, automatic plate shakers, integrated drip tray platform, and robotic filter cloth washing. Filter presses are available in high production capacity Overhead Beam models and smaller capacity Side Beam models, several press sizes and additional options.

Applications for the PHOENIX Filter Press include Aggregate Fines, Coal Refuse, Clean Coal, Mine Tailings, Mineral Concentrates, Dredging Slurries, Water Treatment Sludge, Chemical Waste, and Scrubber Effluent.

The PHOENIX Filter Press: How does it Work?

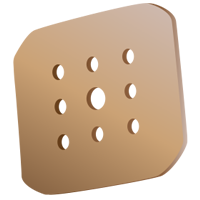

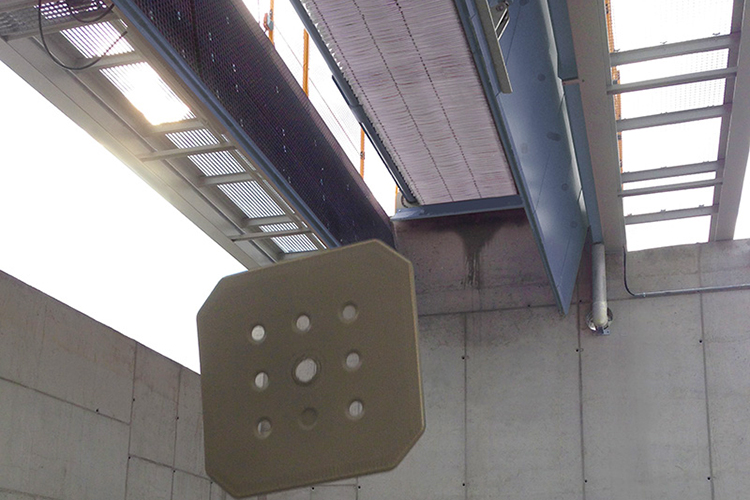

The PHOENIX Filter Press consists of several recessed chambers and filter cloths arranged side by side and held together by a robust steel frame. Each plate is held tightly against one another to seal the spaces in between.

The first step in each cycle begins with a high-pressure pump that feeds slurry into the recessed chambers leaving no empty space between the plates. Once the chamber is full, pressure builds within the chamber and water within the slurry separates through the cloths on each side. As filtered water exits the system, dewatered solids from the slurry are left within the chamber resulting in a high solids filter cake. Then the plates are released and each cake falls to a collection pile below. The robotic high speed plate shifter, equipped with plate shakers, ensures complete discharge of the even the stickiest material. Lastly, a robotic washing system uses high pressure water jets to wash the filter cloths one by one.

PHOENIX Filter Presses feature high speed robotic plate shifters for fast cycle times, automatic plate shakers, integrated drip tray platform, and robotic filter cloth washing. Filter presses are available in high production capacity Overhead Beam models and smaller capacity Side Beam models, several press sizes and additional options.

Applications for the PHOENIX Filter Press include Aggregate Fines, Coal Refuse, Clean Coal, Mine Tailings, Mineral Concentrates, Dredging Slurries, Water Treatment Sludge, Chemical Waste, and Scrubber Effluent.

The PHOENIX Filter Press: How does it Work?

The PHOENIX Filter Press consists of several recessed chambers and filter cloths arranged side by side and held together by a robust steel frame. Each plate is held tightly against one another to seal the spaces in between.

The first step in each cycle begins with a high-pressure pump that feeds slurry into the recessed chambers leaving no empty space between the plates. Once the chamber is full, pressure builds within the chamber and water within the slurry separates through the cloths on each side. As filtered water exits the system, dewatered solids from the slurry are left within the chamber resulting in a high solids filter cake. Then the plates are released and each cake falls to a collection pile below. The robotic high speed plate shifter, equipped with plate shakers, ensures complete discharge of the even the stickiest material. Lastly, a robotic washing system uses high pressure water jets to wash the filter cloths one by one.