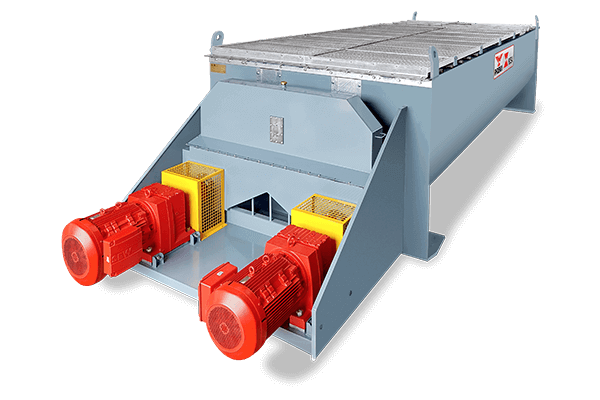

The PHOENIX/KISA twin shaft Logwasher is an essential component of a wash plant's aggregate washing equipment. The Logwasher removes dirt, loam, clay contaminants, and other deleterious materials from raw aggregate materials such as dirty limestone, dolomite, and high silica content gravel. With the capability of handling large rock, high tonnage feed capacities from 220 - 660 STPH and rugged shafts and paddles, our Logwashers are suitable for a variety of applications requiring severe scrubbing and de-agglomeration.

The SWL twin shaft Logwasher is available in several power arrangements and tonnage outputs, including the ability to accommodate rock up to 12 inches.

Applications for the PHOENIX/KISA twin shaft Logwasher include aggregate & gravel washing, coal & wood removal from coarse aggregate, scrubbing coarse lateritic ores, cleaning dirty limestone/dolomite for chemical & cement industries, and demolition waste recycling.

The PHOENIX Logwasher: How does it Work?

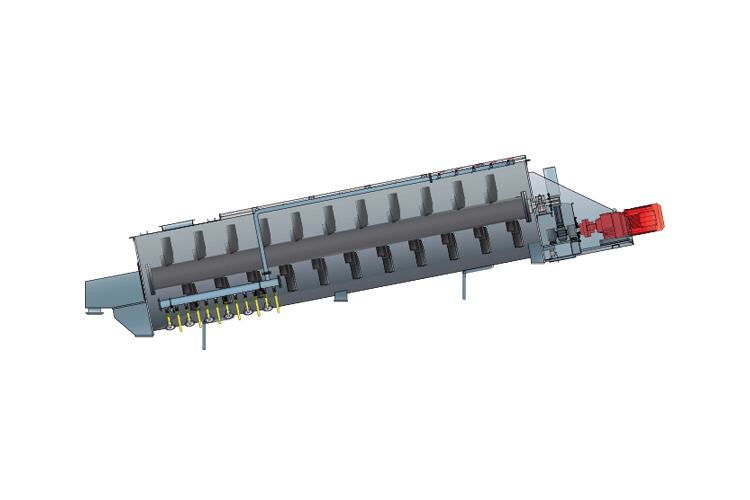

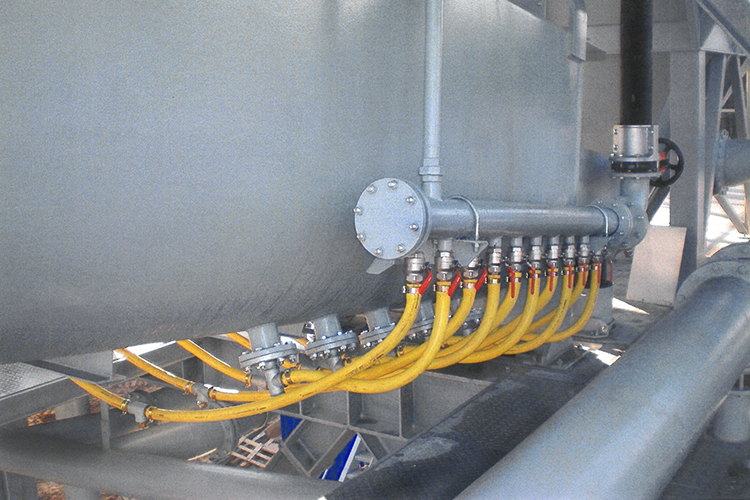

Material is fed to the lower end of the trough. Spray bar arrays at the top end of the trough add water while solid material advances up the inclined trough, as the shafts turn, creating paddle action. From here, force-synchronized, interlocked counterrotating twin shafts with staggered paddles create intense paddle-rock & rock-on-rock shear action to remove the impurities from the material. Finally, scrubbed material dumps from the discharge chute at the top end of the trough and waste liberated fines & low density suspended matter exit through the discharge launders.

The SWL twin shaft Logwasher is available in several power arrangements and tonnage outputs, including the ability to accommodate rock up to 12 inches.

Applications for the PHOENIX/KISA twin shaft Logwasher include aggregate & gravel washing, coal & wood removal from coarse aggregate, scrubbing coarse lateritic ores, cleaning dirty limestone/dolomite for chemical & cement industries, and demolition waste recycling.

The PHOENIX Logwasher: How does it Work?

Material is fed to the lower end of the trough. Spray bar arrays at the top end of the trough add water while solid material advances up the inclined trough, as the shafts turn, creating paddle action. From here, force-synchronized, interlocked counterrotating twin shafts with staggered paddles create intense paddle-rock & rock-on-rock shear action to remove the impurities from the material. Finally, scrubbed material dumps from the discharge chute at the top end of the trough and waste liberated fines & low density suspended matter exit through the discharge launders.